The Best Techniques for Sanding Bondo: A Guide to SYBON's Superior Quality Automotive Filler

When it comes to automotive repairs, sanding Bondo, or any auto body filler, is one of the most important steps in achieving a smooth, professional finish. While Bondo is a trusted name in the industry, not all products are made equal. Here at SYBON, our Bondo auto filler not only offers superior quality but also simplifies the sanding process, helping you achieve feather-edged surfaces with ease. If you're an importer, paint shop owner, or auto repair center manager, our high-quality and competitively priced filler products can significantly boost your business' success and profitability.

In this comprehensive guide, we’ll dive into the best practices for sanding Bondo, why SYBON’s filler is the best on the market, and how you can request samples to see the difference for yourself.

What is Bondo and Why is Sanding Important?

Bondo, a widely recognized product name, is essentially a two-part putty used in automotive body repair. It’s applied to fill in dents, dings, and other imperfections on the surface of a vehicle before it’s primed and painted. After Bondo hardens, the next critical step is sanding, as this process smooths the surface to ensure a flawless finish.

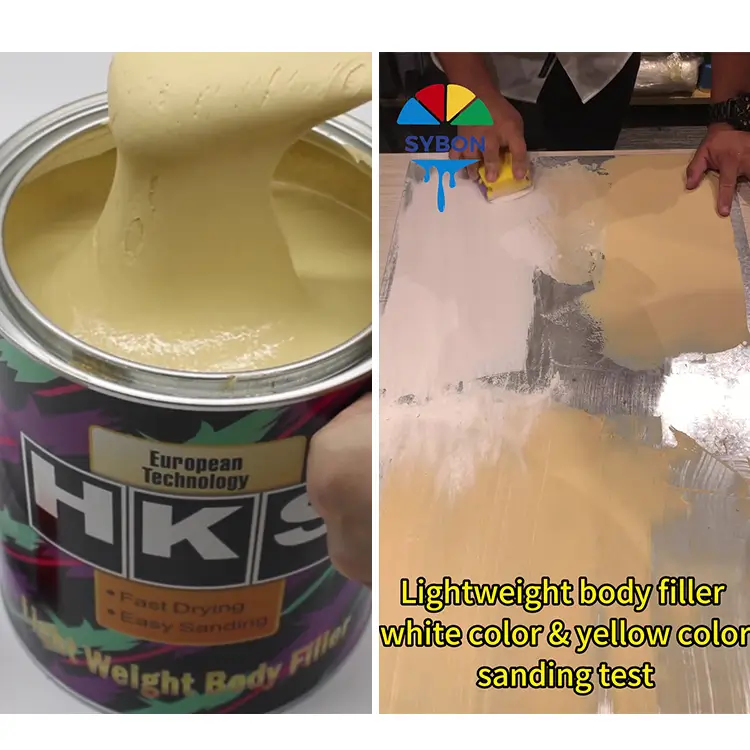

However, sanding Bondo isn’t always easy. The wrong filler can be difficult to sand, leading to an uneven surface or more effort on the part of the user. This is where SYBON's Bondo filler excels. Our filler is formulated to offer an incredibly easy sanding experience. The material responds well to sanding tools, making it a breeze to shape the filler and achieve the smooth feathered edges necessary for seamless paint application.

Why SYBON’s Bondo is Easier to Sand

At SYBON, we've invested heavily in formulating a Bondo filler that strikes the perfect balance between hardness and sandability. Here’s why our Bondo stands out:

1. Feathering Made Easy

With SYBON’s Bondo, sanding down to a feathered edge is no longer a struggle. The filler smooths out beautifully, allowing for a flawless transition from filler to metal without visible seams. This is crucial for achieving a high-quality paint finish without flaws or ridges.

2. Durable and Long-Lasting

While our Bondo is easy to sand, that doesn't mean it's weak. It’s incredibly durable and designed to resist cracking, shrinking, or bubbling over time. This ensures your repairs remain sturdy and smooth for the long haul.

3. Quick Drying for Fast Repairs

Time is money, especially in the automotive repair business. SYBON’s Bondo dries quickly, allowing you to move on to the sanding stage much faster compared to other brands. This efficiency helps increase productivity, which means more repairs and more satisfied customers.

4. Less Clogging

One common issue with sanding Bondo is the filler clogging up the sandpaper. With SYBON’s filler, you’ll notice far less clogging, meaning less time wasted changing sandpaper and more time working on the repair.

Step-by-Step Guide to Sanding SYBON’s Bondo

Now that we’ve discussed why SYBON’s Bondo is superior, let’s walk through the process of properly sanding Bondo for the best possible results.

Step 1: Choose the Right Sandpaper

Selecting the right sandpaper is crucial for successful Bondo sanding. Begin with a coarse grit, such as 80-grit, to shape the filler and remove any excess material. SYBON's Bondo sands smoothly even with coarse grit, making this first stage quicker and easier than many competitors' products.

Once the rough sanding is complete, move on to finer grits, such as 180-grit or 220-grit, to smooth the surface further. SYBON’s Bondo allows for easy transitions between different grit levels, reducing the chances of creating sanding marks or grooves.

Step 2: Sand by Hand or Use Power Tools

For precision work, hand sanding is often the preferred method. Use a sanding block to help maintain even pressure across the surface. This technique ensures a level finish, especially around curves and edges.

If you're working on larger areas, a power sander can speed up the process. SYBON’s Bondo is versatile enough to be sanded by hand or with power tools, offering flexibility based on your needs.

Step 3: Check the Surface Frequently

While sanding, regularly check your progress by running your hand over the surface. Feel for high spots or rough patches. SYBON’s Bondo allows you to easily feel and see imperfections during sanding, making the entire process more efficient. If any imperfections remain, apply a small additional layer of filler, let it cure, and sand again until the surface is flawless.

Step 4: Achieve Feathered Edges

One of the main goals when sanding Bondo is to create feathered edges. Feathering refers to gradually tapering the filler into the surrounding surface so that the transition is seamless and invisible once painted. SYBON’s formula is specially design easy feathering, making this often-difficult task significantly simpler.

Step 5: Finish with a Final Sand

Once you’re happy with the surface, finish with a fine 320-grit or even 400-grit sandpaper for that ultra-smooth finish. After this stage, the vehicle is ready for priming and painting. SYBON’s Bondo ensures that no rough spots or imperfections remain, providing an ideal surface for the next stages of repair.

Why SYBON’s Bondo is the Best Choice for Your Business

SYBON’s Bondo isn’t just easier to sand; it’s a product that delivers value to your business. Whether you're a small auto repair shop or a large-scale distributor, our Bondo filler offers several advantages that make it the ideal choice for professionals.

1. High Quality at Competitive Prices

We understand that quality and cost matter to businesses. SYBON offers premium-grade Bondo filler at prices that are reasonable and accessible for businesses of all sizes. This balance of quality and cost-effectiveness has earned us the trust and loyalty of countless customers worldwide.

2. Trusted by Professionals

SYBON’s Bondo has become a go-to product for auto repair professionals. From body shops to paint centers, our filler has gained a strong reputation for its durability, ease of use, and superior results.

3. Boost Your Profits

When you offer your customers a product that is easier to use, more efficient, and provides outstanding results, it increases both your profitability and customer satisfaction. SYBON’s Bondo allows for quicker repairs, which means more cars fixed in less time.

How to Request Samples and Become a Distributor

At SYBON, we believe in forming strong partnerships with our clients. We invite importers, paint shop owners, and automotive repair centers to request samples of our Bondo filler to experience the SYBON difference firsthand. Our team is dedicated to working with you to meet your specific needs, and we’re confident that our products will help you enhance your business operations.

To request samples or inquire about becoming a distributor, please visit our website and send us an email. We pride ourselves on providing excellent customer service and will respond to all inquiries within 24 hours.

Conclusion

Sanding Bondo is a critical step in automotive repair, but the quality of the filler you use can make all the difference. With SYBON’s high-quality, easy-to-sand Bondo filler, achieving a feathered, flawless surface is no longer a difficult task. Our filler’s superior performance, combined with competitive pricing, makes it the perfect choice for professionals looking to enhance their work efficiency and profitability.

So, whether you’re an importer, paint shop owner, or auto repair center manager, SYBON’s Bondo filler is the key to success. Contact us today to request samples and learn more about how we can help you grow your business.

Source of this article:https://www.supersybon.com

Get to know us through more channels: