Epoxy Primer vs. 2K Primer: Which One is Right for Your Automotive Projects?

When it comes to automotive refinishing, choosing the right primer is essential to ensuring the longevity, durability, and appearance of your paintwork. Two of the most commonly used primers in the industry are epoxy primer and 2K primer. While both serve a similar purpose — providing a stable base for topcoats and enhancing adhesion — they have distinct characteristics that make each suitable for different applications. In this article, we will explore the differences between epoxy primer and 2K primer, helping you decide which is the best choice for your automotive needs.

What is Epoxy Primer?

Epoxy primer is a two-component (2K) system that consists of a resin and a hardener. When mixed, the chemical reaction creates a strong, durable bond on various metal surfaces. Epoxy primers are widely known for their corrosion resistance and ability to adhere to surfaces like bare metal, fiberglass, and aluminum. They are often used in the automotive, marine, and industrial sectors because of their ability to provide long-lasting protection in harsh environments.

Key Benefits of Epoxy Primer:

1. Superior corrosion resistance: Epoxy primers protect metal surfaces from rust and corrosion, especially in environments with high humidity or exposure to salt.

2. Strong adhesion: It bonds well to both old and new surfaces, creating a reliable foundation for subsequent coatings.

3. Durability: Epoxy primers are resistant to chemicals and physical wear, making them ideal for areas subject to heavy use.

What is 2K Primer?

The term 2K primer refers to any primer that consists of two components — a base and a hardener. Similar to epoxy primers, 2K primers are known for their excellent adhesion and durability. However, 2K primers typically focus more on creating a smooth, even surface for the topcoat, offering a level of finish that is often preferred for high-end automotive paint jobs.

Key Benefits of 2K Primer:

1. Smooth finish: 2K primers are often used to create a flawless, even surface for topcoats, especially on vehicles that will undergo cosmetic painting.

2. Flexibility: 2K primers are designed to maintain flexibility, which is crucial for automotive applications where body panels expand and contract with temperature changes.

3. Fast-drying: Many 2K primers have fast-drying formulas, allowing for quicker project turnaround.

Epoxy Primer vs. 2K Primer: Key Differences

1. Composition and Cure Time

- Epoxy Primer: Composed of a resin and hardener, epoxy primers cure chemically over time, usually requiring longer curing periods. This makes them ideal for environments where rust and corrosion are concerns.

- 2K Primer: While also a two-component product, 2K primers typically cure faster and are designed to offer a smooth, finish-ready surface.

2. Corrosion Resistance

- Epoxy Primer: Known for its excellent ability to prevent rust, epoxy primer is the go-to choice for bare metal or areas that are exposed to moisture or harsh chemicals.

- 2K Primer: Though it offers good adhesion, 2K primers do not generally provide the same level of corrosion resistance as epoxy primers.

3. Surface Application

- Epoxy Primer: Best suited for bare metal, fiberglass, and other surfaces prone to rust.

- 2K Primer: Ideal for topcoats where a smooth, even finish is essential, especially on repaired or prepped surfaces.

4. Durability and Flexibility

- Epoxy Primer: Highly durable and resistant to chemical exposure, but less flexible compared to 2K primer.

- 2K Primer: Provides more flexibility, making it better suited for automotive body panels that expand and contract with temperature changes.

5. Purpose

- Epoxy Primer: Primarily used for long-term corrosion protection and sealing.

- 2K Primer: Primarily used for preparing surfaces for high-quality topcoats and offering a smooth, uniform finish.

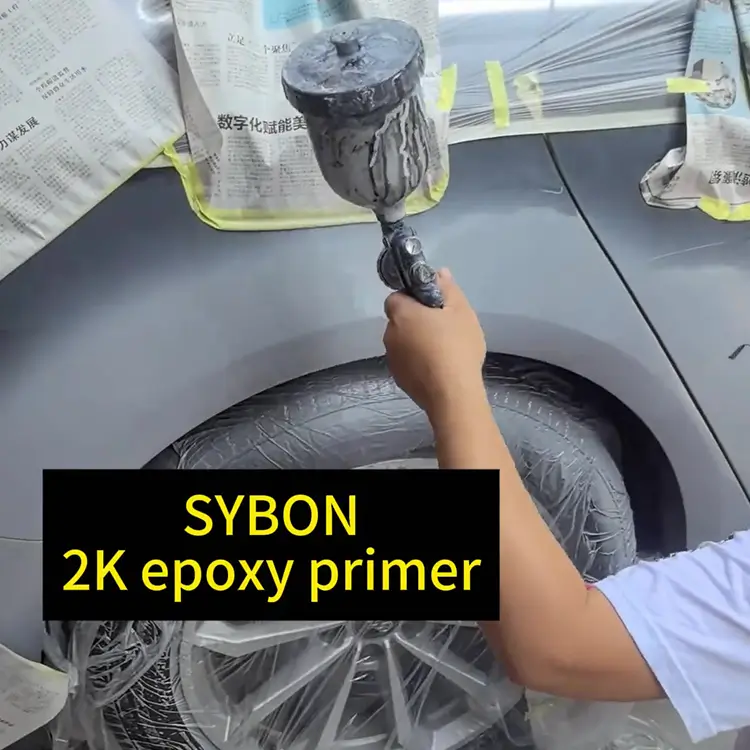

Why Choose SYBON's Epoxy and 2K Primers?

At SYBON, we pride ourselves on producing high-quality and stable automotive primers that cater to a wide range of customer needs. Whether you are working on rust protection with epoxy primer or preparing surfaces for a flawless paint job with 2K primer, we ensure that our products deliver superior performance and value.

Reasons to Choose SYBON:

1. Consistent Quality: Our products are rigorously tested to ensure that they meet industry standards for durability, adhesion, and protection.

2. Competitive Pricing: We offer top-tier products at reasonable prices, allowing you to boost your profit margins without sacrificing quality.

3. Reliable Performance: Our primers provide long-lasting protection and a smooth finish, helping you achieve high-quality results every time.

For Distributors and Auto Repair Centers

If you are a distributor, auto body shop owner, or an automotive repair center looking to expand your offerings, SYBON is the ideal partner. We offer sample requests for testing our products and would love to explore distribution opportunities with you. We are committed to helping you grow your business by offering high-quality primers at competitive prices. Together, we can achieve mutual success.

To request samples or inquire about distribution opportunities, simply contact us through our website, and we will respond within 24 hours.

Conclusion

Choosing the right primer is crucial for ensuring the longevity and appearance of automotive paint jobs. Epoxy primers are perfect for corrosion resistance and durable protection, while 2K primers excel at providing a smooth, even surface for topcoats. Whichever you choose, SYBON offers premium products that meet the demands of professionals in the automotive industry. If you're ready to enhance your business and profit, reach out to us today for samples or to become a distributor.

Contact SYBON now to elevate your automotive projects with high-quality primers!

Source of this article:https://www.supersybon.com

Get to know us through more channels: